MisterAMG took a set of brand-new OEM Mercedes-AMG EQS turbine-style wheels and transformed them into a true masterpiece. The team meticulously refinished each wheel, going through an intricate process to remove the factory black powder coating, revealing the raw, full stainless finish underneath. This wasn’t just a simple strip-and-polish job—each of the turbine wheel’s many nooks, crannies, and sharp contours was carefully worked on to ensure a seamless and flawless result. The process brings out the full potential of the wheel's dynamic turbine design, enhancing the sense of motion even when the car is standing still.

The result is nothing short of extraordinary. The stainless turbine wheels have a striking presence that commands attention. In sunlight, the polished stainless surface gleams, giving the EQS a high-performance, ultra-luxurious appearance that is simultaneously modern and timeless. These wheels seem almost sculptural, offering a level of visual impact that elevates the entire vehicle’s aesthetic to a new echelon of sophistication.

It’s a transformation that begs the question: Why didn’t Mercedes-AMG make this stainless steel finish standard on the EQS? Perhaps the answer lies in the fact that this elevated finish is meant for true connoisseurs—those who appreciate the finer details and are willing to go the extra mile to make their vehicle stand out. The factory black finish may suit the masses, but for those who demand the pinnacle of refinement, the stainless look is unparalleled.

MisterAMG offers this turbine wheel modification as an exclusive service for Mercedes-AMG EQS owners. This ship-in service provides a quick turnaround, ensuring your vehicle’s downtime is minimal while you wait for your upgraded wheels. With a full stainless finish, your EQS will exude a level of style and luxury rarely seen on the road. Ready to make your wheels fully stainless? Get in touch with MisterAMG today, and let the transformation begin.[gallery_single id="eqs-wheels" target="featured_image"]

To best understand how the Wavetrac® is truly different from the other gear differentials on the market, you first have to understand the primary problem that the Wavetrac® solves. The problem: Loss of drive during zero or near-zero axle-load conditions. Zero axle-load is a condition that occurs during normal driving, but creates the most noticeable problems when driving in extreme conditions. Zero or near-zero axle-load is the condition that exists when there is ‘no-load’ applied through the drivetrain, when one drive wheel is nearly or completely lifted (often in aggressive cornering). It also occurs during the transition from engine driving a vehicle to engine braking and back, even with both drive wheels firmly on the ground.

Here’s how that loss of drive hurts you:

1) If you lift a wheel, all gear diffs except Wavetrac®, will NOT power the other wheel.

2) During the transition from accel to decel, all gear diffs except Wavetrac®, do nothing.

Why does this happen?

All gear LSDs (including Torsen®, Truetrac®, Quaife®, Peloquin, OBX, etc.) work in basically the same manner: they divide the drive torque between the two axles, applying drive to each side, up to the available grip of each tire. The amount of drive torque one wheel can get over the other is described as the bias ratio, a measure of the torque split across the axle.

Standard, open differentials have a bias ratio of 1:1. They can only apply as much drive torque as there is available traction at one wheel. When one wheel loses grip, the total available drive is lost as well (at a 1:1 ratio). All your power goes out the slipping wheel - along the path of least resistance.

Torque biasing differentials offer increased bias ratios over open differentials. For example, if a diff has a bias ratio of 2.5:1, then it can apply drive torque to the wheel with the most traction (gripping wheel) at 2.5 times the traction limit of the wheel with the least traction (slipping wheel). This is a significant improvement over an open diff… most of the time.

The problem is that when one tire has LITTLE or NO grip (zero axle-load), the other wheel gets ZERO DRIVE, because (basic math here): 2.5 x 0 = 0.

Lift a wheel (or substantially unload a wheel) and you get zero axle-load on that side - that means that during the time the wheel is unloaded, the typical diff will NOT power the wheel that’s still on the ground. No matter how high the bias ratio, you get no power to the ground.

During the transition from accel to decel, where you have near zero torque on the axle, even if the wheels are on the ground, the typical diff is unable to begin applying drive torque until AFTER the zero torque condition is over. While this condition is generally short-lived, the fact that most diffs can do nothing during that time means that there will be a delay once the zero torque condition stops - creating a reaction time in the driveline.

The Wavetrac®, however, is different:

The innovative, patent-pending, Wavetrac® device in the center of the diff responds during these exact conditions when zero or near-zero axle-load occurs. At or near zero axle-load, the axles (and therefore each side gear in the diff) start to turn at different speeds. This speed differential causes the Wavetrac® device to step into action:

Precisely engineered wave profiles are placed on one side gear and its mating preload hub. As the two side gears rotate relative to each other, each wave surface climbs the other, causing them to move apart. Very quickly, this creates enough internal load within the Wavetrac® to STOP the zero axle-load condition.

The zero axle-load condition is halted, and the drive torque is applied to the wheel on the ground (the gripping wheel)… keeping the power down.

Some gear differentials rely solely on preload springs to combat loss of drive. The drawback is that you can’t add enough preload to prevent loss of drive without creating tremendous handling and wear problems at the same time. So, to avoid these problems, the preload from ordinary spring packs must be reduced to a level that renders them ineffective at preventing loss of drive. The Wavetrac® is the only differential that can automatically add more load internally when it’s required.

In the case where both wheels are on the ground during zero axle load, such as during a transition to deceleration, the Wavetrac® device is able to prepare the drivetrain for when the zero torque condition stops, eliminating the delay seen with ordinary gear diffs.

What this means for you as a driver is that power is delivered to the gripping wheels for more time and in a more constant manner – making you faster and improving stability.

The Wavetrac® truly is different - and its innovative features can make a real difference in your car’s performance.

• Innovative: Patent pending Wavetrac® design automatically improves grip in low traction conditions. This feature is truly innovative and unlike any other torque biasing diff design.

• Superior Materials: 9310 steel gears run in case-hardened billet steel bodies. ARP® fasteners used throughout.

• Maintenance Free: As supplied new, the Wavetrac® differential will perform a lifetime of service without maintenance or rebuilds.

• Customizable: If desired, you can alter the diff’s behavior to suit your needs using optional components.

• Limited LIFETIME Warranty: All Wavetrac® differentials include a transferable, Limited Lifetime Warranty

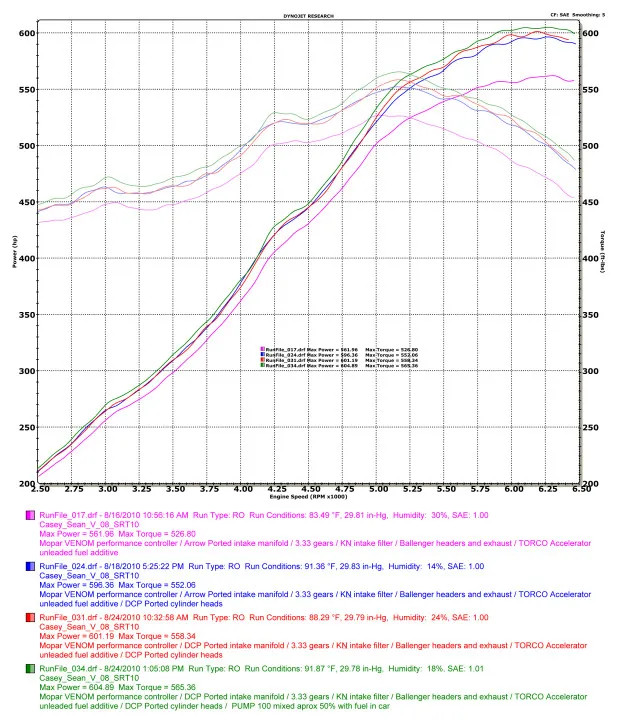

DC Performance does it again! One of our good clients brought us his ACR to upgrade his intake manifold and upgrade to our Supertuned Stage 4 engine package which includes our high velocity ported cylinder heads and intake manifold. Our customer tracks his car on the weekends and this is a great power upgrade for his setup.

Over the past year we have been looking very closely at the Gen 4 Viper engine. With superchargers, turbochargers and big engine builds not practical or economical for most customers with this new engine, we were looking for another 100hp without major internal modifications.

The production bottom end on these Gen 4's has proven very stout with good tri-metal bearings, ARP rod bolts and decent rods. The only limiting factor has been the pistons, so we did not want to increase the piston speed or compression. Another big consideration is the sensitive engine computer, the Venom engine controller is very sensitive to mechanical engines changes and we did not want any check engine lights or "limp" in conditions.

Our performance gains with exhaust and intake modifications have worked really well, the final step for the 100hp gains would need to be in the heads.

With changes to the VVT, cam and compression not viable options, we focused on the cylinder. There has been quite a bit of technology in cylinder head testing with wet flow benches and injector spray pattern analysis, so we thought a good look at the heads would yield some big power gains.

Our big focus on a head modification was to maximize air-velocity through the primary choke area of the intake and exhaust ports. Engines runs on velocity and not just cfm numbers. The area under the seat is critical and can be improved dramatically.

With our ported heads done and ready to test, our next concern was clamp load on the head and block. We wanted to do everything possible to keep the bore straight. The production head bolts are inexpensive and are borrowed from the passenger car line, so we opted for an ARP bolt set to finish off our package.

Our last concern was oil pull through in to the intake manifold from the PCV system. These engines are very sensitive to knock. On many engines that we tested, we have data-logged the knock control and found the computer retarding timing. This hurts power and can lead to piston issues. Oil in the intake and related carbon deposits increase knock (detonation). Our solution was a air-oil canister that does not allow the oil to migrate into the manifold.

Our testing was done on a 2008 Viper with Belanger headers and exhaust, Arrow intake and Mopar controller. Gains were 30-32rwhp in an AB test. Futher testing with our intake and better fuel added another 7 rear wheel horsepower. Air fuel was very safe and no check engine lights or "limp in" conditions were encountered.

Our criteria for testing was very controlled, each test was performed at the same engine coolant temp and heat soak. Our initial test was a before and after test of the heads. The only variables other than the head change was the removal of carbon from the piston tops, new plugs and an oil-air separator for the PCV system.

Initial Test with Ported Heads:

34 hp and 26 lb-ft torque

Next test was to remove the Arrow intake and install our ported intake.

Ported Heads + Intake:

5 hp and 6 lb-ft torque (increase on top of Ported Heads)

Our final test was to raise the octane level to about 95

Ported Heads + Intake + Octane:

3 hp and 7 lb-ft torque (increase on top of Ported Heads and Intake)

For those of you who want the most from your Gen 4 Viper engine with good reliabilty, this is THE option! Please feel free to call us with any questions you may have. I am always available via PM.

We are taking orders!

This badass “Reimagined by Singer” machine is based on the 964 model, 911 chasis of 1990-1994. Boasting a more sophisticated platform than past restorations by Singer, this gem is painted Singer Racing Silver with a Ruby Red interior. This is the fourth machine to be restored and handcrafted for an owner by Singer. Singer’s founder and creative director Rob Dickinson believes this machine boasts a combination of touring, luxury and sporting options that while seem extravagant, attempts to create the perfect gentleman’s sports car for the road.

Singer feels it is a torch bearer of the great coach building traditions of the 1920s and 1930s, brought up-to-date for the 21st century and utilizes new technologies and fresh perspectives. Dickinson believes “Grand ideas would be impossible to implement without the incredible network of skilled specialists that exist here in Southern California – from world-class upholstering to cutting-edge composite technology, from unique nickel plating and polishing developments to state-of-the-art rapid prototyping and manufacturing.”

After nearly four years of passionate restoration of its first three optimized, air-cooled Porsche 911s provided to their owners, Singer recently entered the next phase in the advancement of its company with two key partnerships – internationally-renowned motorsport engineers The Cosworth Group is Singer’s exclusive supplier of engines, and composite experts Aria Group prepares, paints and outfits the carbon fiber bodies utilized in Singer restorations.

Pricing reflects this no-expense-spared approach with owners choosing from a comprehensive range of restorative and modification services ranging from $190,000 to more than $300,000. Singer works collaboratively with each owner to personalize a machine to their own specific tastes.

SVD offers a full range of engine options, with three tiers of performance levels:

Touring – 3.6-liter engine, producing 300 hp

Sport – 3.9-liter engine, producing 360 hp

Cup – 3.9 to 4.0-liter engine, producing more than 400 hp

These engines will present state-of-the-art thinking and development in all areas of the Singer restored Porsche® air- cooled unit with optimization in-cylinder head design, fuel injection, intake and exhaust, to name a few.

DC Performance was excited and honored to be chosen to help tune this rare Porsche restoration. In conjunction with Apex Speed Technology, this tuned piece of art was brought to DC Performance to utilize our Dynapack Dynamometer. DC Performance is your one-stop service and performance center located in Los Angeles.

[gallery_single id="singer-porsche" target="featured_image"]